- 公式HPリンク

- トータルエンジニアリング

- SAKE Brewery Interview (酒蔵記事)

- 記事制作について

- The Art of Sake Brewing 1

- The Art of Sake Brewing 1(ENG)

- The Art of Sake Brewing 2

- The Art of Sake Brewing 2(ENG)

- The Art of Sake Brewing 3

- The Art of Sake Brewing 3(ENG)

- The Art of Sake Brewing 4

- The Art of Sake Brewing 4(ENG)

- The Art of Sake Brewing 5

- The Art of Sake Brewing 5(ENG)

- The Art of Sake Brewing 6

- The Art of Sake Brewing 6 (ENG)

- The Art of Sake Brewing 7

- The Art of Sake Brewing 7 (ENG)

- 設備デザイン

- 展示会・セミナー

- FTIC(未来技術革新委員会)

- 補助金サポート

- 生産性向上要件証明書

- 微生物インダストリープラットフォーム

- Enz Koji

- 一般食品

- お問い合わせ

The Art of Sake Brewing (vol.1)_English

“Someday, I want to make sake as beautiful as Mt.Fuji”

ー Tsukasabotan Brewery Co.,Ltd. Chief brewer Toru Asano

[Interview Contents]

This article is also available as a Podcast.

Brew the sake that represents Kochi

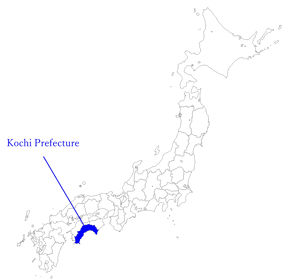

Tsukasabotan Brewery is located in Kochi Prefecture, which is in the southern part of Shikoku Island. After one hour drive from Kochi City to the west, you will reach a small town called Sakawa, where Tsukasabotan has brewed sake for more than 420 years.

Sakawa is surrounded by mountains full of nature. No wonder the town has nurtured a world-famous botanist, Tomitaro Makino (1862-1957). The scenery changes every season. When we visited there, Kawazu-zakura, an early-flowering variety of cherry tree, was in its full bloom.

Although Kochi Prefecture generally is known for its warm climate, it gets rather cold in the evenings and early mornings in Sakawa. This unique climate enables Tsukasabotan Brewery to brew one of Kochi’s iconic sake. They steam rice early in the morning and takes in the cold air to cool it off. They also control microorganisms in accordance with the changing outside temperature.

“I think it’s important to reflect Sakawa’s nature, climate, and food culture in the taste of sake we make. I know that sweet and clear sake full of flavor has been popular recently. To make such sake, cold climate is idealistic. But we, as a brewery in Kochi, dare to brew thick and dry sake with a hint of acidity. Thanks to the warm climate in daytime, we can generate moderate acidity. And luckily enough, Niyodogawa* river system provides us with the best water for our sake. Plus, thick dry sake goes very well with our local fish, like Bonito and Tsuna”.

*Niyodogawa: Niyodogawa as known as Niyodo River runs through near the center of Kochi Prefecture. It flows from Mt. Ishizuchi, the highest mountain in western Japan, and has been selected as one of “rivers with the best water quality” six times in the past 10 years (2014-2023) by the Ministry of Land, Infrastructure, Transport and Tourism.

Tsukasabotan’s flagship “Senchu-Hassaku”, and the keys to determine the taste

Senchu Hassaku

The flagship brand “Senchu Hassaku” represents the very taste of Tsukasabotan’s sake. The key to generate the taste is the combination of their original koji style and temperature it’s fermented.

“We use 100% Yamadanishiki for kakemai*, and we polish the grain down to 60%”, says Asano. Yamadanishiki is a high-quality rice variety, developed specifically for sake brewing. The variety of kakemai hadn’t been unified before, but Asano decided to use Yamadanishiki only at the expense of postponing brewing process.

By polishing the rice down to 60%, it becomes a perfect fit for ginjo-shu. However, Asano doesn’t adopt tsuki-haze koji style, which is the style for ginjo-shu production. Instead, “we aim at the intermediate koji style; between tsuki-haze and sou-haze”.

Using highly polished Yamadanishiki, adopting the intermediate koji style, and adjusting temperature and timing for kirikaeshi* generate the originality and complexity of “Senchu Hassaku”.

*kakemai: Rice added to moromi (mash) in the process of fermentation.

cf. kojimai: Rice used to make koji. Also known as malted rice.

*ginjo-shu: Ginjo-shu is a type of sake with 60% or less rice remaining. A type of sake with 50% or less rice remaining is called Dai-ginjo. Ginjo-shu and Daiginjo-shu tend to be fragrant and relatively light sake.

*tsuki-haze:If the koji is tsuki-haze style, hyphae are sparsely propagated on the surface of rice, but fully propagated inside.

*sou-haze: If the koji is sou-haze style, hyphae cover the surface of the rice and also propagated inside.

*kirikaeshi: Kirikaeshi, also called “turnover”, is one of several stages of koji production process.

The Tsukasabotan

Another product named “The Tsukasabotan” expresses the terroir of Kochi. For the ingredient, they use Yamadanishiki produced only in Kochi.

Because Kochi faces typhoon every summer, it’s considered difficult to grow Yamadanishiki, which is taller and easier to fall compared to a regular kind of rice. However, by applying the natural farming called Nagata method, developed by a scientist Terukichi Nagata, they succeeded to grow strong and healthy Yamadanishiki resistant to typhoon.

“Our Yamadanishiki may not look pretty compared to those grown in the famous production area in Hyogo, but it’s flavor is unmistakenly Yamadanisiki. Also, some rice grown in Sakawa area especially match very well with the water we use for our sake”.

Asano’s goal is to limit rice used for Tsukasabotan’s sake only to the rice produced in Shikoku island and prefectures surrounding the Setouchi Inland Sea.

“Sake with an impression of harmony and a wide range of aftertaste is beautiful.”

In the process of sake brewing, a chief brewer put all their senses and philosophies as well as techniques and experiences.

“Someday, I want to make sake just as beautiful as Mt.Fuji”.

This was an answer Asano gave us when we asked him what’s his ultimate sake is like.

“Mt.Fuji rises in solitary and well-balanced in itself. Beautiful sake shouldn’t be simply clean or clear. It should be beautiful, embracing various flavors, fragrances, and texture, while giving an impression of harmony and a wide range of aftertaste. I don’t know how long it takes for me to reach that level but that’s what I am ultimately aiming at”.

Chief brewer Toru Asano

Asano brews sake with 12 men and women with the help of machines made by Fujiwara Techno-Art Co., Ltd (FTA). The total amount of sake Tsukasabotan Brewery produces per year is more than 5,000 goku (about 238,271gal.). To maintain both quantity and quality, Tsukasabotan Brewery implemented a series of “Ginjo-kura products” by FTA 2005 when they decided to build a new kura called “Heisei-gura”.

Tsukasabotan Brewery "Heisei-gura"

“I was totally O.K. with the idea of mechanizing the process of sake production. We are such a small group of people to produce 5,000goku, so we use machines as tools. The important thing is that we humans are the one who design koji style and make a great use of tools based on our experiences and deep understanding about koji”.

As is mentioned before, chief brewers’ senses and philosophies are reflected in the product-sake- they make. Same thing is said about the machines they choose.

“VEX is the machine I’ve been looking for”; best tool for Asano’s koji production

Asano had been looking for the best machine to make his ideal koji just like he does by hand. That was when Asano saw the presentation of FTA’s VEX.

VEX is the machine invented for koji production process. It’s based on the idea of traditional koji production method called “futa-koji-ho”. The whole picture of the machine looks like a huge box or a tiny room, in which there is a shelf to lay koji. In the room, the temperature and humidity is maintained at certain level, and the koji layer is covered with VEX laminate to release steam from the top and the bottom of the layer at the same amount each. The temperature inside the koji layer is automatically controlled thanks to the laminate and the water vaporing system. Since there is no air current inside the space covered by the laminate, you can control and maintain the quality of koji as you design.

After seeing FTA’s machines used at one of the trusted breweries in Niigata, Asano thought, “this is it. I can count on FTA. VEX is the machine I have been looking for”.

VEX along with other machines from Ginjo-kura products have been used in Heisei-gura of Tsukasabotan Brewery for almost twenty years.

“I love the simplicity of VEX. It consists of a few parts, and the idea applied to the machine is also simple, based on the traditional way of koji production”.

While it can be used to make 300kg of koji for regular Junmai sake, it can also be used to make only 30kg koji for dai-ginjo sake. “I can experiment various styles. That’s another thing I like about VEX”, says Asano.

For instance, the “rotary automatic rice washing and soaking machine” rinses rice perfectly and reaches the very percentage of water the rice should absorb. Recently developed version of “*Ginjo steamer” is another Asano’s favorite.

Old version of “Divided Ginjo steamer” used to face challenges such as sparsely steamed rice and unstable percentage of water the steamed rice contains. FTA persistently repeated trial and error to turn the old version into the developed version. “I can’t be satisfied more, I should say”, Asano now speaks highly of FTA’s Koshiki.

*Ginjo steamer: Koshiki is a traditional equipment for steaming rice.

“The biggest pro for using machines is that we can constantly produce a good amount of high-quality sake”, says Asano. “Not to mention efficiency. We can wash and soak a lot of rice at once. If we prepare extra storage tank, we can even produce two tons of ginjo-sake”. For a middle-sized brewery like Tsukasabotan, balancing efficiency and quality of the product is the point that cannot be overlooked.

Rotary automatic rice washing and soaking machine

Koshiki:"Ginjo steamer"

Tsukasabotan Brewery has brewed their iconic sake without being influenced by trend. With the help of technology, they are passing on their history of 420 years and “the sake of Kochi” to today.

The catalog of the equipment introduced in this article.

Fujiwara Techno-Art develops machinery and plants for about 27 countries around the world, and exports comprehensive technologies including design, manufacturing, installation, and follow-up services. Some of the products introduced in this article have also been exported overseas.

フォームが表示されるまでしばらくお待ち下さい。

恐れ入りますが、しばらくお待ちいただいてもフォームが表示されない場合は、こちらまでお問い合わせください。