- 公式HPリンク

- トータルエンジニアリング

- SAKE Brewery Interview (酒蔵記事)

- 記事制作について

- The Art of Sake Brewing 1

- The Art of Sake Brewing 1(ENG)

- The Art of Sake Brewing 2

- The Art of Sake Brewing 2(ENG)

- The Art of Sake Brewing 3

- The Art of Sake Brewing 3(ENG)

- The Art of Sake Brewing 4

- The Art of Sake Brewing 4(ENG)

- The Art of Sake Brewing 5

- The Art of Sake Brewing 5(ENG)

- The Art of Sake Brewing 6

- The Art of Sake Brewing 6 (ENG)

- The Art of Sake Brewing 7

- The Art of Sake Brewing 7 (ENG)

- 設備デザイン

- 展示会・セミナー

- FTIC(未来技術革新委員会)

- 補助金サポート

- 生産性向上要件証明書

- 微生物インダストリープラットフォーム

- Enz Koji

- 一般食品

- お問い合わせ

The Art of Sake Brewing (vol.3)_English

Delivering Stable Gekkeikan Quality;

“No matter what kind of ball comes our way, we hit the goal.”

― Gekkeikan Co., Ltd. Brewing Department, Group Leader of the Ote 1st Brewery, Mitsuru Sakamoto

[Interview Contents]

This article is also available as a Podcast.

■ Leading Innovation in the Sake-brewing Industry

From the Azuchi-Momoyama period to the Edo period, the town of Fushimi flourished as a key transportation hub and post town connecting Osaka and Kyoto. It has long been blessed with traditional sake brewing techniques and abundant underground water. By 1657, there were eighty-three sake breweries in this bustling area, frequented by travelers and goods. One of the most historic sake breweries in Kyoto, Gekkeikan Co., Ltd., was founded in 1637 and has been a leading force in the sake industry's innovation while carrying forward the legacy of Fushimi's sake.

According to Mitsuru Sakamoto, the Group Leader of the Ote 1st Brewery at Gekkeikan's Brewing Department, Fushimi's sake is characterized by its "mild, subtly sweet flavor." The brewing water is medium-hard, with 50–60 ppm hardness, which "allows the yeast to ferment well, producing a refined finish."

Another unique feature of Fushimi's sake is the "yondan-jikomi (four-stage mashing process)". At the end of the fermentation process (at the fourth stage), they add steamed rice to the mash to impart a natural sweetness. "Perhaps due to its development alongside Kyoto's court cuisine, it has a clean, refined taste that goes well with Kyoto-style dishes," says Sakamoto.

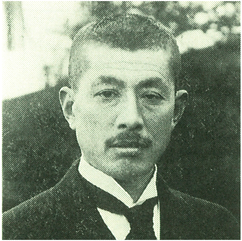

As the times shifted from the Edo period to the modern era, Gekkeikan grew into a top-tier sake brewery. A key figure in this growth was the 11th head of the family, Tsunekichi Okura, who founded the Okura Sake Brewing Research Institute, the predecessor of today's Gekkeikan General Research Institute.

Tsunekichi, who had a close friendship with Chikashi Kanomata, a technician at the National Research Institute of Brewing, quickly recognized the potential of scientific advancement and, in 1909, became the first in the sake industry to establish a research institute. He hired Hide Hamazaki, a graduate of Tokyo Imperial University, as the first head technician. This research institute later achieved the commercialization of bottled sake without preservatives, bringing about a major transformation in the sake industry.

The Gekkeikan General Research Institute has continued to drive research and development related to sake, focusing on areas such as koji mold, yeast, and solid culture. The institute has produced many innovative products, including the recent "Kagetsu", a sake with fruity aromas like peach, melon, and grape. The product was born thanks to the data accumulated at the research institute, the careful selection of yeast, and innovations in the brewing process.

11th head of the family, Tsunekichi Okura

Commercialization of “preservative-free bottled liquor"

”Kagetsu”, a new type of sake with a fruity aroma

Image courtesy of Gekkeikan Co., Ltd.

Scientifically Unlocking the Secrets of Sake Brewing;

“The quality control team is the conductor, and the brewing team is the performer.”

Mitsuru Sakamoto discusses the role of the research institute and the production technology section.

At Gekkeikan, the research institute plays the crucial role of "scientifically unlocking the secrets of sake brewing," says Sakamoto. "The research institute breaks down the brewing process, which has traditionally relied on the intuition and experience of master brewers. It also analyzes the mash and the sake, identifying both positive and negative elements." For instance, after uncovering the essence of "ginjo-ka (fruity aroma)," the institute determines exactly what actions at which stages of the process are needed to achieve that aroma. The results of the analysis are quantified and recorded to ensure consistency and reproducibility.

Sakamoto highlights that the quality control team plays an important role in maintaining stable quality while maintaining large-scale production. Gekkeikan’s sake has a consistent characteristic of being "slightly sweet and with a refreshing aftertaste, so you won’t get tired of drinking it." Delivering such stable quality to any location at any time is a value that a company like Gekkeikan, with its extensive data-driven quality control, can offer.

The company produces a broad range of 700 to 800 products, including variations in packaging sizes. "Each type of sake has its own specific goal," says Sakamoto. The goals, in other words, the flavor profiles are defined by the company. Based on the flavor profile, standards such as extract content and glucose levels are regulated to fall within a specified range. According to Sakamoto, "the quality control team and the brewing team have worked together over generations to preserve and pass down 'the Gekkeikan flavor.'"

"If the quality control team is the conductor, then the brewing team is the performer, " Sakamoto says. To achieve the quality the "conductor" seeks, the company adopts a collaborative approach: "If we can achieve the desired quality through the current blending, we proceed. If not, we try brewing it within the brewing group, and the research institute works on development. Once it’s developed, the brewing group works on ensuring reproducibility," utilizing both analytical and technical capabilities for product development.

"Our brewing group has the skill to achieve the desired quality, even though there are variations in raw materials. While I understand that designing and creating toji(master brewer)’s own sake is appealing, I find it pretty interesting and satisfying to always hit the goal no matter what kind of ball comes our way."

The Teachings of the Master Craftsman:

“Observe and gain insight into the koji and the mash”

In Gekkeikan’s Ote 2nd Brewery, fourteen soaking tanks, each capable of processing five tons of rice, are lined up, and the production site boasts an impressive 160 fermentation tanks. The scale of the machinery is extraordinary, with two steam rice machines capable of steaming four tons of rice per hour and six koji production machines capable of handling six tons each.

"Because of the size of the brewery, safety is our top priority," says Sakamoto. "If used correctly, machines will always produce ideal results. However, the larger the scale, the greater the impact of any troubles that occur. I always make sure that our workers aren’t taking unnecessary risks and that they’re working safely."

The brewing leader's role differs somewhat from that of a traditional toji who oversees the entire process from design to execution. In large companies like Gekkeikan, the designing process and the brewing process are separated, and various departments work together to create sake. However, Sakamoto emphasizes that "both toji and brewing leaders share the same careful attention to raw materials, mash, and the finished sake." By sensing the characteristics of the machine and the state of the material, they make various adjustments.

Both toji and brewing leaders require strong observational skills. "Since we're working with microorganisms, observing every step of the process is critical. It’s not just 'seeing' but 'observing,'" says Sakamoto. "Yoshinori Otaki, who was recognized as a ‘Kyoto Master Craftsman (Kyo-no-Meisho)’ in 2017, also said, 'Observe and gain insight into the koji and the mash.' The important thing is whether you can notice slightest things by observing the target. This applies not just to sake brewing, but to any profession."

While the brewing team’s keen observation is vital, the company’s strength cannot be fully explained without mentioning the quality control team. "When the brewing group brings koji to the analysis department, they have the data ready by the next week. If improvements are necessary, we make adjustments based on the vast amounts of data accumulated. We are blessed with a wonderful environment to aim for the goal," says Sakamoto.

Despite the company's advanced analytical capabilities, Sakamoto notes that there’s still unknown elements of sake. "There are countless elements and brewing components that don’t show up in analysis results, and there are infinite variables. Even when the analytical values are the same, the taste can vary. It's fun to think, 'what could be causing this?' while reviewing the processes with my colleagues and engaging in trial and error," he says with a smile.

"Ichi-koji, Ni-moto, San-tsukuri (First Koji, Second Seed mash, Third Brewing; three important steps in sake brewing) ", is one of the deep factors that do not easily appear in analytical data but have a significant influence on the quality of the final product. Currently, Sakamoto is deliberately fixing the yeast and trying to refine the foundation of the steps.

The foundation of the steps lies in processing raw materials and koji-making. And throughout the important steps, Gekkeikan makes good use of the machines manufactured by Fujiwara Techno-Art.

Realizing On-site Ideals

For the washing and soaking steps of brewing ginjo sake, the "Limited Absorption Rice Washing and Soaking Machine" is used. Isamu Kasai, formerly of the Gekkeikan Brewing Department, first came up with the idea that it would be nice to have a machine that mimics washing by hand. Based on his idea, the technical teams of both companies collaborated to create a fully automated device that replicates manual work.

When asked about its performance, Sakamoto commented, "it has high precision, resulting in just the right amount of water absorption. Since the first step of water absorption in raw material processing is crucial, we carefully observe it."

In the koji-making process that follows raw material processing, the "Rotary type automatic Koji making equipment" is used. Gekkeikan’s Ote 2nd Brewery had used the old version of the machine for a long time. However, when they updated the aging facility, they decided to implement the bigger and improved version. The weak points of the previous facility were washability and sterilization. Gekkeikan and Fujiwara Techno-Art made a great improvement to enhance hygiene so much. As a result, "when we check the koji for bacteria, almost no general bacteria are detected. Off-flavors caused by bacteria are also well prevented," says Sakamoto.

Regarding the use of the six "Rotary type automatic Koji making equipment”, Sakamoto stated, "They are so comfortable to use. The sheer volume we handle here is impossible for manual labor. Not only have we achieved a significant reduction in manpower by introducing the machine, but we've also been able to maintain high precision in humidity and temperature control."

When making koji for specific sakes like "Yamada Nishiki Junmai," Sakamoto noted that "we adjust the cultivation pattern and dehumidification control to make it easier to produce tsuki-haze, the koji style ideal for ginjo sake production. Because the machine is so stable, the brewers can focus on their craft," he said, demonstrating the high level of his technical skill in utilizing the machinery.

The "Pow Feeder” connected to the Rotary type automatic Koji making equipment prevents the koji spores from being scattered in the room, eliminating the need to wash the floor with water. This keeps the room dry, making it harder for harmful mold to grow. The device also allows for evenly controlled amounts of koji spores to be dispersed.

Inside of Koji Making Equipment

Full view of koji molding equipment (3D model)

Pow Feeder (Powder seed mold supplying device)

Regarding utilizing machines in brewing process, Sakamoto shared an interesting story. "There was a team leader and a younger brewer. The young brewer was doing his job like a familiar job, and the team leader cheerfully asked him, 'are you working with the desire to make it delicious?' This lightened the mood of the workplace, and I thought, 'could the unmeasurable elements in sake come from moments like this?' Perhaps these small emotional connections with the equipment and tools lead to better-tasting sake."

"Horin" a Special Sake for a Special Occasion

"Horin" a sake perfect for special occasions or as a premium gift, is a luxurious junmai-ginjo or junmai-daiginjo sake. To enhance its refined, clean, and elegant taste, Sakamoto and his colleagues chose the yeast to strengthen the banana-like aroma of isoamyl acetate, rather than the apple-like aroma of ethyl caproate.

Regarding the koji used in "Horin," Sakamoto explained, "since we're using plenty of rice for this product, it would be a waste not to bring out the flavor of the rice. The common practice in brewing ginjo sake is to aim for tsuki-haze style, but to bring out more flavor, we allow the koji to absorb a certain amount of moisture while maintaining a balance of enzymes." Achieving such koji requires precise control in the washing and soaking steps, as mentioned earlier. By observing the texture and condition of the rice on that particular day, they carefully adjust the parameters for the steaming and cooling equipment.

Fujiwara Techno-Art's “VEX” is used to make “Horin” koji.

"THE SHOT" – Pioneering New Scenes for Sake

THE SHOT

"THE SHOT" series feature four types – "Brilliant&Dry (Daiginjo)," "Glossy&Rich (Honjozo)," "Elegant&Smooth (Junmai Ginjo)," and "Full-bodied&Classical (Josen Nama-zume)". This series not only stands out for its flavor but also for its package design. The container is easy to hold, with a resealable cap, allowing even people who don't usually drink sake to enjoy it. Aiming at creating new scenes for sake, this product seeks to cater to those moments when one wants to enjoy sake casually.

Gekkeikan’s Charm Lies in Familiarity

TSUKI

The domestic sake industry is facing a shrinking market due to a combination of factors such as a declining birthrate, an aging population, an increase in choices of alcoholic beverages, and a lack of interest in sake among younger generations. Gekkeikan, a long-established leader in the sake world, is now aiming to add higher value to sake and create new contexts for its enjoyment. Products such as fruity "Kagetsu," the premium "Horin," and the stylish "THE SHOT" series are representative of this direction.

On the other hand, Sakamoto emphasized that "the strength of products like 'Tsuki (the Moon)' and 'Gekkeikan Josen' lies in their familiarity." They can be enjoyed as a part of everyday lives. Sake that fits seamlessly into daily meals at an affordable price is something Gekkeikan, with its advanced equipment and technical expertise, can provide.

"As I get older, I find sake more and more delicious. It's comforting and soothing. Sake is a drink born and developed in Japan, so it probably suits my body. Even though the domestic market is shrinking, I believe sake will never disappear from Japanese people’s ordinary lives," said Sakamoto.

When asked what kind of sake he wants to create in the future, he replied, "I want to make a sake that everyone loves. Ideally, people would say, 'I've always drank this sake thinking it was delicious. I didn't know which company made it, but it was Gekkeikan.'"

Gekkeikan is so widely known in Japan that it is no exaggeration to say that there is no adult in Japan who does not know its name. Even if the label didn’t bear the name, the quality of the sake itself would tell you everything you need to know.

Image courtesy of Gekkeikan Co., Ltd.

Catalog of equipment featured in this article

Fujiwara Techno-Art develops machinery and plants for about 27 countries around the world, and exports comprehensive technologies including design, manufacturing, installation, and follow-up services. Some of the products introduced in this article have also been exported overseas.

Contact Us

フォームが表示されるまでしばらくお待ち下さい。

恐れ入りますが、しばらくお待ちいただいてもフォームが表示されない場合は、こちらまでお問い合わせください。