- 公式HPリンク

- トータルエンジニアリング

- SAKE Brewery Interview (酒蔵記事)

- 記事制作について

- The Art of Sake Brewing 1

- The Art of Sake Brewing 1(ENG)

- The Art of Sake Brewing 2

- The Art of Sake Brewing 2(ENG)

- The Art of Sake Brewing 3

- The Art of Sake Brewing 3(ENG)

- The Art of Sake Brewing 4

- The Art of Sake Brewing 4(ENG)

- The Art of Sake Brewing 5

- The Art of Sake Brewing 5(ENG)

- The Art of Sake Brewing 6

- The Art of Sake Brewing 6 (ENG)

- The Art of Sake Brewing 7

- The Art of Sake Brewing 7 (ENG)

- 設備デザイン

- 展示会・セミナー

- FTIC(未来技術革新委員会)

- 補助金サポート

- 生産性向上要件証明書

- 微生物インダストリープラットフォーム

- Enz Koji

- 一般食品

- お問い合わせ

The Art of Sake Brewing (vol.4)

Riding the waves of change, embracing the winds of challenge, and sailing toward the future

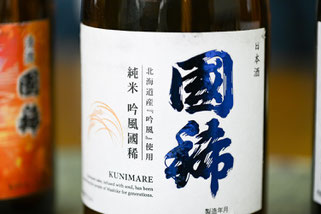

Kunimare Sake Brewery Co., Ltd.

President, Kaori HAYASHI

Executive Officer, Chief Manager, Tetsuji MIZUGUCHI

Manufacturing Group, Section Manager, Yusuke SUGANO

[Interview Contents]

This article is also available as a Podcast.

Mashike Town, located in the northwestern part of Hokkaido, used to prosper from herring fishery overlooking the majestic Sea of Japan. The town is home to Kunimare Sake Brewery (Kunimare), which has a history of over 140 years. Since its founding, Kunimare has consistently placed importance on its commitment to the community. In recent years, the brewery has pursued high-quality sake production using locally grown rice; therefore earned acclaim both within and outside Hokkaido, including winning gold awards at the Annual Japan Sake Awards. We interviewed them regarding Kunimare’s journey and thoughts behind their sake-making, their collaboration with the community, and their outlook on the future.

The history developed along with the herring fishery

Kunimare Sake Brewery's predecessor, "Maruichi Honma," was founded in Mashike Town in 1882, when the prosperous era of herring fishing just started. The herring fishery had been the backbone of the town's industry for a long time since then.

Originally operating as a kimono shop, Kunimare's founder, Taizo Honma, acquired fishing rights for herring in 1881 and ventured into the fishing industry. At the fishing site, teams of twenty to thirty workers, ranging from fishermen to boat repairers, worked together. These workers, who gathered from regions like Tohoku and southern Hokkaido, lived communally in lodgings during the fishing season. As a result, sake became a significant item during gatherings like welcome parties, celebrations of bountiful catches, and farewell parties.

The sea of Mashike, where herring fishing thrived.

Taizo's journal shows the evidence of comparative considerations between buying sake and brewing it himself. Taizo, the great-grandfather of the current president, Kaori Hayashi, made a calculated decision to brew their own sake. President Hayashi remarks, "He must have meticulously calculated before deciding to start brewing." She further describes his diligent and precise nature, saying, "His journals contain detailed records of annual production numbers and prices for sake brewing. It reflects his character."

The former merchant house "Maruichi Honma House," the residence of Taizo Honma, was originally established as a drapery business and expanded with the growth of fisheries and sake brewing.

Although the sake brewing initially began for personal consumption, the booming herring fishery in Mashike stimulated related industries, such as fish processing. Observing the growing population and increased demand for sake, Taizo established a stone-built brewery in 1902, one block away from the original site, to produce sake for sale.

The factory, warehouses, and office building of Kunimare Sake Brewery were renovated and constructed to harmonize with the existing old stone buildings.

However, in the post-war period around 1955, Mashike's herring fishery rapidly declined, and the demand for sake also decreased drastically. Despite the hardship, Kunimare did not give up brewing sake and kept on contributing to the community.

Revival of Kunimare during the shochu* boom

President, Kaori Hayashi

When shochu was booming all over Japan, Kunimare launched key products such as "Onikoroshi," "Daiginjo," "Junmai Kunimare," and "Honjozo" between 1985 and 1988. This coincided with the opening of National Route 231, connecting Hokkaido’s biggest city Sapporo and Mashike’s neighboring city Rumoi. The new road attracted the tourists from Sapporo as well as boosted interactions with restaurants in Sapporo.

In the spring of 2002, the brewery converted its former kitchen into a shop and renovated a stone warehouse used as a storage facility into an exhibition room. Reflecting on this period, President Hayashi says, "We upgraded our brewery equipment over several years to meet the growing demand while also enhancing the tour experience."

As they increased production capacity, they recognized the need for investments in equipment to ensure a stable supply of high-quality sake. Then-president and current chairman, Shinji Hayashi, made a bold decision to move forward.

*shochu: a distilled liquor born in Japan

A partnership with Fujiwara Techno-Art for quality excellence

Between 2000 and 2004, Kunimare introduced cutting-edge brewing equipment. Among the selected machinery was Fujiwara Techno-Art’s products, with an interesting backstory behind the partnership. The pivotal moment occurred in 2002, when Fujiwara Techno-Art’s chairman at the time attended Kunimare's chairman’s funeral in Mashike. This act of respect left a strong impression on the family, and mutual trust laid the foundation for introducing Fujiwara Techno-Art's machinery.

The brewing site of Kunimare Sake Brewery is equipped with Fujiwara Techno Art’s “VEX,” as well as a "soaking tank," a " rice steamer," and a "net-type continuous cooler."

The incorporation of these advanced machines brought dramatic improvements in sake quality. Manufacturing Manager, Tetsuji Mizuguchi says, “we use VEX to make koji for regular sake such as “Kasen” and “Onikoroshi.” VEX is an automatic koji making machine that is completely ventilation-free. It was developed to produce tsuki-haze* koji suitable for ginjo sake. Mizuguchi says, “VEX adopts a thin-layer koji production method that incorporates the idea of traditional futa-koji*. Furthermore, it automatically adjusts the temperature of the product twenty-four hours without ventilation. It is an extremely excellent machine that can produce tsuki-haze efficiently and stably. The reason why our former president chose such a machine must have been because he had a strong desire to make high quality sake.''

*tsuki-haze: If the koji is tsuki-haze style, hyphae are sparsely propagated on the surface of rice, but fully propagated inside.

*futa-koji: a traditional koji-making method using trays

Approximately 70% of Kunimare Sake Brewery’s sales composition consists of “Kasen,” “Oni Koroshi,” and “Tokubetsu Junmai.”

“Kasen” is brewed luxuriously, with a polishing ratio of 65% and the use of “VEX” for koji-making.

Although the capital investment was made in response to increased demand, Mizuguchi points out, “The equipment was probably too large considering the production volume at the time.” President Hayashi says with a laugh, “Back then, the production volume was about half of what it is now. Other breweries used to ask me, ‘Why did you have such a high hope?’” As the quality of sake improved, the demand and the production volume increased, and the “hope” finally became a reality.

Executive Officer, Chief Manager, Tetsuji MIZUGUCHI

Manufacturing Group, Section Manager, Yusuke SUGANO

The introduction of VEX not only improved sake quality but also contributed to work efficiency. Yusuke Sugano, Manager of the Manufacturing Group, says, “Because VEX is controlled based on a pre-input program, temperature control and turning are done automatically. Thanks to the machine, we were able to significantly reduce our workload, including night and weekend work.”

President Hayashi admits the effect of installing Fujiwara Techno-Art’s machines and equipment. “We've been able to reduce the labor of our employees, and we've also been able to improve the quality of sake.”

Because of the location in northwestern Hokkaido, it is not easy to immediately repair it on-site when a mechanical problem occurs. That is why detailed after-sales follow-up and maintenance based on trust is important. When asked about what to do in the event of a problem, Sugano gave us the following answer:

“Of course, it takes time if the malfunction needs replacement of some parts. However, if the problem is of a certain extent, Fujiwara Techno-Art's sales representative can give us repair tips over the phone. If that doesn't work, they kindly connect you with the person in charge of manufacturing, and I can talk to them about various things without being frustrated. "

Commitment to the local rice and love for the town

In the early 2000s, Kunimare was at a turning point in terms of raw materials, as it turned to expand and update its facilities. They began brewing sake using locally grown rice.

In 2000, a new kind of sake rice called "Ginpu" was developed. Kunimare has strengthened their collaboration with local rice farmers, and currently, 60% of the rice used at the brewery is produced only in Mashike Town, maintaining a completely community-based approach. “I remember with deep emotion the first time we brewed sake using Mashike’s ‘Ginpu’,” says President Hayashi.

“The combination of advances in farmers' rice cultivation techniques and improvements in our sake brewing techniques has enabled us to produce sake of even better quality,'' Sugano adds. “We want to use local ingredients and make sake loved by the local community. With that in mind, we have continued to improve our techniques that have been inherited over Kunimare’s history.” The love for the region nurtured over many years and the relationships with local farmers have become a foundation of Kunimare's sake brewing.

A new challenge: Passing the baton to the next generation

Kunimare has been experiencing another major transition recently. Their long-serving toji (master brewer) retired in 2024. This can be a big challenge for Kunimare because they have to replace the toji’s intuition and experience with standardized process and techniques.

“The toji who supported our brewing was an expert of koji-making and was very good at making elegant sake. That taste became one of our goals and has been passed down on Kunimare,” says Mizuguchi. On the other hand, he emphasizes, “When thinking about passing on our sake brewing to future generations, we cannot rely on a particular toji’s intuition and experiences.” Mizuguchi adds, “It is necessary to have the ability to use all five senses to evaluate sake and to check for off-tastes and odors. However, if we focus only on individuals’ senses, we will not be able to continue sake brewing. The number of people engaged in sake brewing has been decreasing. When thinking about the future of sake brewing, we cannot ignore the perspective of standardization."

Mizuguchi also says, “In order to standardize brewing process to some extent, the use of high-performance machinery like VEX is essential." Good machines enable precise quality control based on data. By mastering these machines, stable sake quality can be achieved no matter who is in charge. “This is a major change from the days when we relied on the techniques of a toji. At the same time, it is also an important step in passing on techniques to future generations,” says Mizuguchi.

Mechanization of all brewing processes has not yet been completed, and there is still room for standardization. Regarding the future, Sugano says, “I would like to eliminate inconsistencies and inefficiencies as much as possible. Although we have refrained from mechanization out of respect for the toji’s opinion, we are now open to various opinions from other members within the manufacturing department.''

The absence of the toji poses a major challenge for Kunimare, but at the same time, holds new possibilities. “Up until now, we have worked mainly with the toji and followed his instructions on a day-to-day basis. However, from now on, we will actively incorporate the opinions of each and every employee at the manufacturing site to create better sake from a multifaceted perspective. We would like to create something new,'' says Sugano. “Starting with the sake brewing in 2024, we use the VEX to make Daiginjo koji. The VEX was originally developed for making koji for Ginjo class and above. I think it will go well,'' he says with high expectations.

Mizuguchi also expresses his enthusiasm for the challenge under the new system. “The sake brewing led by a toji will change to the one carried out in collaborative way. It might be difficult at times, but there are things that you will only understand after failures. It is important to give it a shot. No matter how good a machine is, you will not be able to take full advantage of it unless you try something new. I want to keep taking on challenges.”

From Hokkaido to the world

Kunimare, which has established a solid customer base in Hokkaido, is now looking to future growth.

One direction is developing overseas markets. They started overseas expansion about ten years ago and currently export sake mainly to Southeast Asia. President Hayashi frankly describes the market’s reaction, “Although most people are interested in sake, they don't fully understand it yet. That's why we must take on the challenge. We are willing to communicate the appeal of sake to people around the world."

Kunimare has hired two employees from Taiwan. The two, who are fluent in English and Mandarin, use social media and other media to disseminate information to the world in multiple languages. Kunimare also produced sake called “MARE” just for overseas markets. The name is easy to pronounce and remember, and the blue bottle represents the beautiful Sea of Japan.

Another direction is to increase their recognition in the domestic market by leveraging the customer base Kunimare has cultivated over many years. Sugano, who is devoted to quality control, values delivering sake supported by today’s customers. He says, “I want to make sure that there is no discrepancy between what we think ‘tasty’ and what customers think ‘tasty’. Therefore, we pay close attention to everything from the blending ratio to the storage environment."

"MARE" for the overseas market.

“MARE” means "sea" in Latin.

One of Kunimare’s strengths is having a shop where they directly sell their sake to their customers. Customers visiting the shop can sample sake casually. Sugano says that the Manufacturing Group adjusts their product based on feedback from customers and the Sales Department and sales trends. “We want to continue to create sake loved and supported by customers.”

Kunimare Sake Brewery has created a history while staying close to the rise and fall of Mashike Town. President Hayashi says cheerfully, “We will continue trying various things without being afraid of change.'' Japan's northernmost sake brewery has evolved through flexible changes based on its passion for the local community. Now that they have entered a new phase, Kunimare has set sail to further challenges.

The catalog of the equipment introduced in this article.

Fujiwara Techno-Art develops machinery and plants for about 27 countries around the world, and exports comprehensive technologies including design, manufacturing, installation, and follow-up services. Some of the products introduced in this article have also been exported overseas.

Contact us

フォームが表示されるまでしばらくお待ち下さい。

恐れ入りますが、しばらくお待ちいただいてもフォームが表示されない場合は、こちらまでお問い合わせください。